MOJ S.A.

Tokarska 6 Street, 40-859 Katowice

T: +48 (32) 604 09 00

F: +48 (32) 604 09 01

E: sekretariat@moj.com.pl

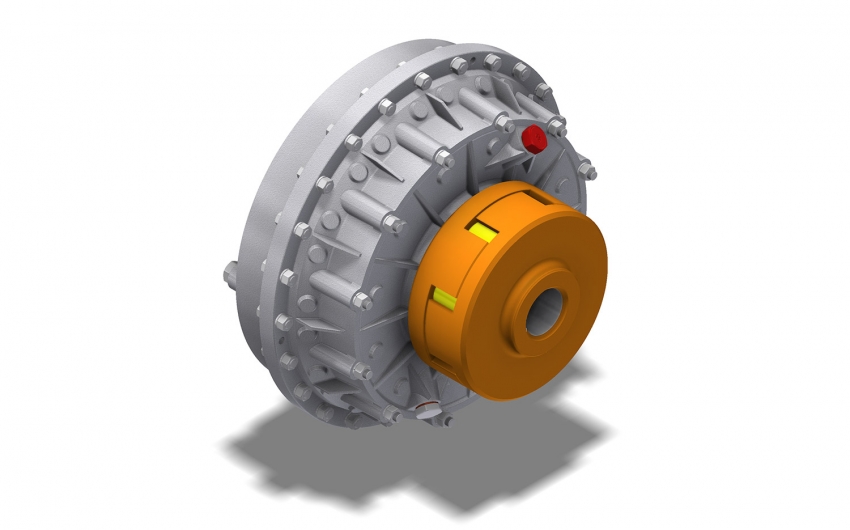

Hydrokinetic couplings of type SH are designed for use in drives of machines with high inertia, operated under heavy traffic conditions and subjected to significant and intense overloads.

The application of the hydrokinetic coupling of type SH contributes to mitigating the starting of the drive, reducing the operating time of the electric motor at high currents, damping sudden impacts and inhibitions, and compensating for dynamic overloads.

The primary application of the hydrokinetic coupling is to transmit the torque from the drive motor to the working machine. Hydrokinetic starting and overload couplings are used in drives of machines that have to operate in harsh working conditions and are exposed to strong and intense overloads. The couplingis installed between the motor and the reduction gearbox to protect the drive unit (motor) from damage by mitigating sudden events and rapidly changing torque values.

Examples of applications for hydrokinetic couplings of type SH include: single-drive and multiple-drive systems for scrap and belt conveyors, plow drives, crushers, mill drums, etc.

These couplings can be used in machines intended for operation in underground mines in zones "a," "b," and "c" of methane explosion hazard and A and B of coal dust explosion hazard, including belt and scrap conveyors, coal plows, crushers, pumps and mills, rotary kilns, elevators, crushers, draw machines, and winches.

The motor and machine can be selected for continuous operation conditions, not for starting.

| Type of HYDROKINETIC COUPLING | Motor Rated Torque Mzn Nm |

Motor Speed n RPM |

Force Transmitted by the Coupling N kW |

CouplingTorque Mmax Nm |

Coupling Engagement Torque Mr Nm |

Fill Volume dm3 | Smoothness s % |

Coupling Weight kg |

|

|---|---|---|---|---|---|---|---|---|---|

| HLP-32 Hydraulic Oil | Water-Oil Emulsion 5% | ||||||||

| SH-55E | 367 | 1470 | 55 | 720 | 780 | 11,7 | 10,5 | 2,5 | 82 |

| 366 | 920 | 12,5 | 11,3 | ||||||

| SH- 100/75E | 492 | 1470 | 75 | 975 | 1080 | 14,3 | 13,4 | ||

| 608 | 90 | 1330 | 1350 | 15,6 | 14,5 | 3,0 | 110 | ||

| 660 | 100 | 1280 | 1300 | 15,7 |

|

||||

| SH-132/110E | 726 | 1470 | 110 | 1750 | 1750 | 19,2 | 18,1 | 3,0 | 152 |

| 870 | 132 | 2100 | 2150 | 20,3 | 2,5 | ||||

| SH-160 | 1560 | 985 | 160 | 2900 | 2970 | 45,0 | 43,9 | 10,3 | 263 |