MOJ S.A.

Tokarska 6 Street, 40-859 Katowice

T: +48 (32) 604 09 00

F: +48 (32) 604 09 01

E: sekretariat@moj.com.pl

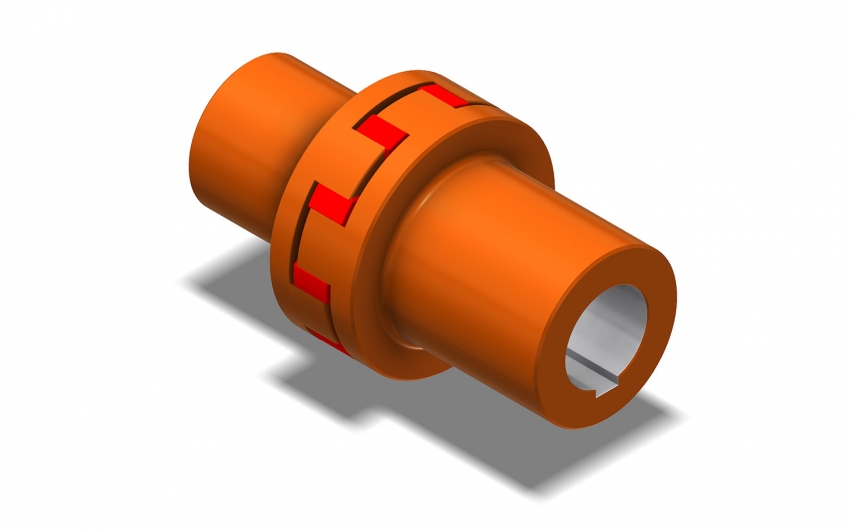

The basic SP coupling consists of two claw hubs and a flexible insert. The shape of the claws, hubs, and the flexible insert ensures optimal interaction even when the alignment of the motor and the driven device shafts is not precise.

The elastic inserts commonly used in couplings have a hardness of 92ºSh A by default. Inserts with a hardness ranging from 80ºSh A to 98ºSh A can also be used. Thanks to the properties of the elastic insert, these couplings are frequently employed in drive systems with high dynamic loads, including those powered by electric, combustion, or hydraulic motors. They are designed for drives that require a constant speed with a simple start-up.

Working in an environment with a pH range of 5 to 12 within a temperature range of -30°C to +80°C (temporarily up to +100°C). Chemical resistance includes, among others, common solvents, gasoline, oils and fats, sulfuric acid, hydrochloric acid, caustic soda, and saltwater.

The elastic coupling SP can be used in drives for conveyor systems, feeders, elevators, fan hydraulic pumps, crushing machines, compressors, mills, and drying facilities. The coupling can be used in temperatures ranging from -20°C to +80°C.

| Size | Elastic Insert | Torque | Rotating Speed nmax [rpm] |

Outer Diameter of the Coupling [mm] |

||

|---|---|---|---|---|---|---|

| Type | Operating Temperature [0C] | Mzn [Nm] | Mmax [Nm] | |||

| Insert Polyurethane 92 ShA | ||||||

| SP 19R | R19 | -40÷+90 | 10 | 20 | 14000 | 41 |

| SP 24R | R24 | 35 | 70 | 10600 | 56 | |

| SP 28R | R28 | 95 | 190 | 8500 | 65 | |

| SP 38R | R38 | 190 | 380 | 7100 | 80 | |

| SP 42R | R42 | 265 | 530 | 6000 | 95 | |

| SP 48R | R48 | 310 | 620 | 5600 | 105 | |

| SP 55R | R55 | 410 | 820 | 4750 | 120 | |

| SP 65R | R65 | 625 | 1250 | 4250 | 135 | |

| SP 75R | R75 | 1280 | 2560 | 3550 | 160 | |

| SP 90R | R90 | 2400 | 4800 | 2800 | 200 | |

| SP 100R | R100 | 3300 | 6600 | 2500 | 225 | |

| SP 110R | R110 | 4800 | 9600 | 2240 | 255 | |

| SP 125R | R125 | 6650 | 13300 | 2000 | 290 | |

| SP 140R | R140 | 8550 | 17100 | 1800 | 320 | |

| SP 160R | R160 | 12800 | 25600 | 1500 | 370 | |

| SP 180R | R180 | 18650 | 37300 | 1400 | 420 | |

| Insert Polyurethane 98 ShA | ||||||

| SP 19R | R19 | -30÷+90 | 17 | 34 | 14000 | 41 |

| SP 24R | R24 | 60 | 120 | 10600 | 56 | |

| SP 28R | R28 | 160 | 320 | 8500 | 65 | |

| SP 38R | R38 | 325 | 650 | 7100 | 80 | |

| SP 42R | R42 | 450 | 900 | 6000 | 95 | |

| SP 48R | R48 | 525 | 1050 | 5600 | 105 | |

| SP 55R | R55 | 685 | 1370 | 4750 | 120 | |

| SP 65R | R65 | 940 | 1880 | 4250 | 135 | |

| SP 75R | R75 | 1920 | 3840 | 3550 | 160 | |

| SP 90R | R90 | 3600 | 7200 | 2800 | 200 | |

| SP 100R | R100 | 4950 | 9900 | 2500 | 225 | |

| SP 110R | R110 | 7200 | 14400 | 2240 | 255 | |

| SP 125R | R125 | 10000 | 20000 | 2000 | 290 | |

| SP 140R | R140 | 12800 | 25600 | 1800 | 320 | |

| SP 160R | R160 | 19200 | 38400 | 1500 | 370 | |

| SP 180R | R180 | 28000 | 56000 | 1400 | 420 | |

| Insert Polyurethane 64 Sh-D-F | ||||||

| SP 19R | R19 | -30÷+110 | 21 | 42 | 14000 | 41 |

| SP 24R | R24 | 75 | 150 | 10600 | 56 | |

| SP 28R | R28 | 200 | 400 | 8500 | 65 | |

| SP 38R | R38 | 405 | 810 | 7100 | 80 | |

| SP 42R | R42 | 560 | 1120 | 6000 | 95 | |

| SP 48R | R48 | 655 | 1310 | 5600 | 105 | |

| SP 55R | R55 | 825 | 1650 | 4750 | 120 | |

| SP 65R | R65 | 1175 | 2350 | 4250 | 135 | |

| SP 75R | R75 | 2400 | 4800 | 3550 | 160 | |

| SP 90R | R90 | 4500 | 9000 | 2800 | 200 | |

| SP 100R | R100 | 6185 | 12370 | 2500 | 225 | |

| SP 110R | R110 | 9000 | 18000 | 2240 | 255 | |

| SP 125R | R125 | 12500 | 25000 | 2000 | 290 | |

| SP 140R | R140 | 16000 | 32000 | 1800 | 320 | |

| SP 160R | R160 | 24000 | 48000 | 1500 | 370 | |

| SP 180R | R180 | 35000 | 70000 | 1400 | 420 | |

| Insert PA, PEEK | ||||||

| SP 19R | R19 | -20÷+130 | 30 | 60 | 14000 | 41 |

| SP 24R | R24 | 105 | 210 | 10600 | 56 | |

| SP 28R | R28 | 280 | 560 | 8500 | 65 | |

| SP 38R | R38 | 565 | 1130 | 7100 | 80 | |

| SP 42R | R42 | 785 | 1570 | 6000 | 95 | |

| SP 48R | R48 | 915 | 1830 | 5600 | 105 | |

| SP 55R | R55 | 1200 | 2400 | 4750 | 120 | |

| SP 65R | R65 | 1645 | 3290 | 4250 | 135 | |

| SP 75R | R75 | 2560 | 5130 | 3550 | 160 | |

| SP 90R | R90 | 6300 | 12600 | 2800 | 200 | |

| SP 100R | R100 | 8650 | 17300 | 2500 | 225 | |

| SP 110R | R110 | 10500 | 21000 | 2240 | 255 | |

| SP 125R | R125 | 13000 | 26000 | 2000 | 290 | |